Managed to snag a great deal on this 6" King Industrial bench top jointer. It looks to be the same as similar models from Rikon, Wahuda, etc. Early tests are promising and I’m looking forward to increasing my ability to mill small rough lumber.

Managed to snag a great deal on this 6" King Industrial bench top jointer. It looks to be the same as similar models from Rikon, Wahuda, etc. Early tests are promising and I’m looking forward to increasing my ability to mill small rough lumber.

Been building a mobile stand for my new toy — a 10” bench top bandsaw from Rikon. I researched options for a long time and this feels like a good fit. Solid construction, cast iron table, a good fence, and 5” of resaw capacity. Excited to start adding it to my workflow.

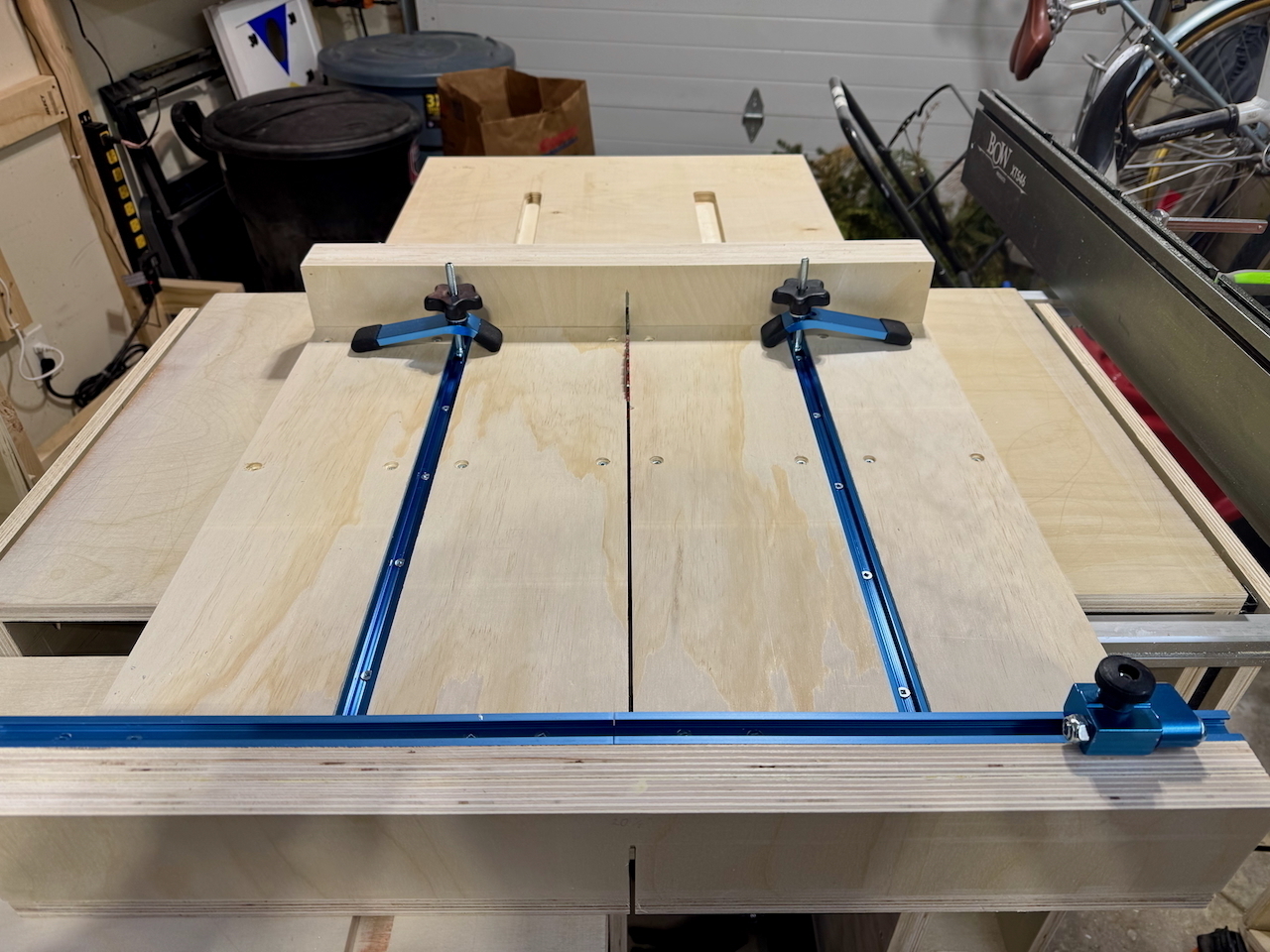

The second iteration of my crosscut sled, which has thoroughly replaced my mitre saw for most tasks. Just over 20 1/2" deep and constructed from 3/4" plywood it — combined with the extra infeed support on my table saw cart — allows me to crosscut some pretty wide stock. The end stop was carried over from my previous sled, but the hold-down clamps are new and already proving useful.

The third iteration of my table saw cart. I don’t have the space for a proper table saw, but I’ve had great luck with this DeWalt DWE7485 job site saw. I added outfeed support with mitre slot extensions, side wings, and infeed support. All of which fold down for storage. Combined with the Bow Xtender fence, I’ve been able to cut some sizeable stock on this setup.

Quick shot of my previous dust collection setup. The good ol' “shop-vac and cyclone on a bucket” setup served me well for a very long time. I added a twist by 3D-printing a wye and some blast gates, which let me swap between a long hose for the big tools (table saw, router table, etc) and handheld tools at the bench. I’ve since added a dedicated dust collector for the big stuff.